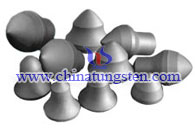

Cemented Carbide Parabolic Buttons

| Cemented Carbide Parabolic Buttons |

|

Cemented carbide parabolic buttons are the main parts of road digging machine-milling machine which are mainly used for the protection and repairing of roads. Only cemented carbide parabolic buttons have good hardness and impact resistance can the milling machine work efficiently. Chinatungsten Online can provide various sizes of cemented carbide parabolic buttons according to customers' specific requirements.

Cemented carbide parabolic buttons are sinters from WC-Co powder with low pressure. With properties of good wear resistance, impact resistance and long service life, cemented carbide parabolic buttons are widely applied in the construction of airport, wharf, express way,etc.

Advantages of cemented carbide parabolic buttons from Chinatungsten Online:

1.The metallographic structure of cemented carbide parabolic buttons is tight, effectively reducing the microscopic pores in the alloy.

2.Cemented carbide parabolic buttons have good toughness, strong resistance to high temperature and high wear resistance and its service life is generally 5 to 20 times longer than parabolic buttons made from other materials.

3.Good quality and reasonable price of cemented carbide parabolic buttons from Chinatungsten Online.

Grades of cemented carbide parabolic buttons

| Grade | Density g/cm³ | TRS MPa | Hardness HRA | Performance & application recommended |

| YG4C | 15.10 | 1800 | 90.0 | Mainly used as small buttons for percussion bits to cut soft and medium hard formations. |

| YG6 | 14.95 | 1900 | 90.5 | For coring crowns, electric coal drill bits, coal cutting picks, oil cone bits and scraping knife bits, used in geological prospecting, coal mining and oil well boring. |

| YG8 | 14.80 | 2200 | 89.5 | For coring crowns, electric coal drill bits, coal cutting picks, oil cone bits and scraping knife bits, used in geological prospecting, coal mining and oil well boring. |

| YK05 | 14.95 | 2500 | 90.5 | Mostly used as the buttons of small and medium sized percussion bits and as the inserts of rotary prospecting bits to cut soft and medium hard formations. |

| YG8C | 14.80 | 2400 | 88.5 | |

| YK15 | 14.60 | 2450 | 87.6 | Suitable to strips, conical buttons for rotary percussion-resistant, geological prospection buttons, cut soft and medium hard formations. |

| YK20 | 14.40 | 2500 | 86.8 | Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and hard formations. |

| YK25 | 14.40 | 2550 | 87.2 | Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and very hard formations. |

| YG11C | 14.40 | 2700 | 86.5 | Largely for the inserts and buttons of percussion bits and tricone bits to cut medium-hard, hard, and very hard formations. |

| YG13C | 14.2 | 2850 | 86.0 | Primarily for the buttons of tricone bits and inserts of rotary percussion bits to cut hard and very hard formations. |

| YG15C | 14.0 | 3000 | 85.5 | For oil cone drill bits, for medium soft and medium-hard |

sales@chinatungsten.com

sales@chinatungsten.com