Cemented Carbide Tool Applications

Milling Application Notes

Cemented carbide tools:

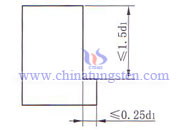

Should try to choose the best rigidity, the maximum diameter of the slot length shortest and the shortest total length end mills

Long edge cutter does not apply to the cavity milling, slotting or strong profiling - limited Rw 0.02D

High-performance tool has a shorter processing time, a longer life

Handle:

The shank is required to have sufficient clamping force and a sufficiently small rotary beating

Recommended use for heavy cutting short and thick entities the shank or zero length collets shank

The using entity shank, is not recommended to use the manual wrench

Artifact:

Firmly clamp the workpiece will reduce tremor and deflection

Machine:

To ensure the hilt achieve maximum run out accuracy and tool life, the spindle must be in the best condition

To achieve the recommended speed and feed rate, the machine should have sufficient power

To prevent damage to the workpiece or tool for low-power machines should reduce the amount of feed

Cooling:

The jet law or liquid coolant to avoid swarf "secondary milling"

Cleaning and having an appropriate concentration to maintain the cooling liquid

General recommendations:

Water-soluble oil or jet law: tool steel, tool steel, carbon steel or alloy steel;

Water-soluble oil: stainless steel, titanium, high temperature alloys, non-ferrous metals.

Method:

Recommends using climb milling

Attention to detail, shank, jumping, balancing, fixture. Improve tool performance and extend tool life.

Universal cutting tool types: d1 = cutting diameter, l2 = slot length

| Slotted | Profiling | Fine milling |

|

|

|

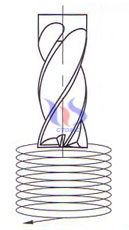

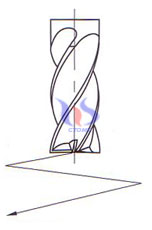

Feed mode

| Pre-drilled feed | Spiral feed | Oblique feed | Vertical feed |

|

|

|

|

| Most applications are recommended pre-drilled feed | The helical feed and oblique feed as an alternative, when the lower knife slotted speed and 25-50% slotted feed rate. General tool feed angle is 5 °, the feed angle of the high-performance tool is 5% to 10%. | Only cutting non-ferrous metals and short chipping materials can be selected vertical feed under the knife slotted speed and 25% slotted feed rate | |

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com