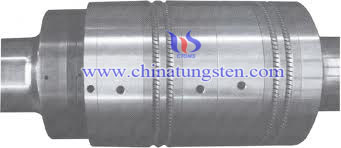

Composite Cemented Carbide Roll Installation

Cemented carbide roller is a high-tech means to create the high temperature thermal cracking of high-performance roller, the correct roll pass processing, maintenance, and can greatly improve the rational use of rolling destroy rolling tonnage, improve rolling stability, the mill production work rate and negative deviation rate. If used improperly, it will produce rolled destroy chunk off the meat, severe depth of the crack of the cemented carbide roller until the roll cracking scrapped, resulting in a serious waste (cemented carbide roller price to high NiCr roll the times). To be reasonable, scientifically cemented carbide roller, reducing the roll consumption, lower production costs, reduce labor intensity of the operator, to offer you the following cemented carbide roller note, for reference.

|

| Composite Cemented CarbideRoll Installation |

1.Roll installation, hole pattern processing requirements (metalworking shop)

(1)Composite cemented carbide roll finished product delivery status of the outside diameter of 300mm-450mm, the roll surface length 450mm of 600mm integral shaft-like structure, to be installed in the corresponding rack.

(2)All parts and fasteners installed before cemented carbide roller surface condition of the components in good condition before installation.

(3)Roll lathe work according to specifications and equipped with roller requirements, choose the right cemented carbide roller tools, grades, seriously, carefully turning hole pattern. Grinding machine manufacturers roll grinder processing results will be better. Lathes and grinding machine model should carefully check the error should be less than 0.05 mm.

(4)Should be turning hole pattern caused cracks in the rolling completely removed, and deepen about 0.2mm, clear the hidden dangers left by the previous processing cycle.

(5)Hole pattern after turning, and then require milling roll transverse ribs slot milling machine work before milling transverse ribs slot, so the drill shank the aligned hole pattern center, transverse rib tank in the center of the hole pattern mark lettering accurately placed in the jump rib location.

(6)Roll the inspector slot hole and transverse ribs acceptance, processing, after passing the lifting rolling.

2.Roller bearing seat installation and pre-installed rack guide and guard installation (rolling workshop)

(1)Cemented carbide roller bearing inner ring installation: the assembly should be noted that the accuracy of the bearing inner ring and maximize the use of the new inner ring, the inner ring heating temperature, time requirements, to prevent overheating caused by the inner ring hardness decreased, thereby reducing the life of the bearing operation.

(2)Roll chocks should be used in good condition bearing outer ring, check rolling elements and cage and outer ring raceway groove surface state, qualified as a dedicated bearing seat, and coloring markers.

(3)Cemented carbide roller rings parts roller assembly should be protected from the impact.

(4)Pre-installed rack mount cooling pipe installation is very important, special pipes installed in the roll up and down rolling groove exit and aligned with the rolling groove with screws. After installing, the team leader should sign a special form to show acceptance. Replacement of rolling groove, use the same method, cross to the next class production.

(5)Steps: the cemented carbide roller in the pre-installed rack mount, and then required to load into the export guide and guard on the mill exit, and then, the next roll rolling groove required into the curved cooling pipes, when the team leader on the acceptance form signed and approved, and then sent along with the roll card control room, control room in the arrangement of the pair of roll-on, and acceptance form when the team leader. When the team leader in class cooling water and roll temperature check, test results also be signed off until the post to the next team leader, this acceptance form as a quality record, the end of the life cycle, the shelf life of three months, to prepare for query.

(6)The online roll chocks dry oil grease should ensure that the join once every 24 hours.

(7)Composite cemented carbide roll and slot without any grease, dirt and other spots.

Chinatungsten Online can provide various sizes and grades of cemented carbide products,deep processing and mold design and production , non-standard products can also be customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com