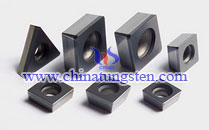

Mechanical Clamped Inserts

| Cemented carbide mechanically clamped inserts refer to a mechanical method of positioning, clamping blade. Cemented carbdie mechanically clamped inserts can be used for processing cylindrical clip, face, inner hole, and the advantage of using cemented carbide mechanically clamped inserts is to avoid the defects caused by welding. The insert holders can be used multiple times, and the geometry design is flexible. Centralized sharpening is good for improving insert quality, convenient management, reducing costs and so on. | Mechanical Clamped Inserts |

|

With high wear resistance and high strength, cemented carbide is usually be used for cemented carbide mechanical clamped inserts, which can be applied to cast iron, stainless steel, alloy steel etc. Now we supply cemented carbide turning inserts, milling inserts, thread turning and cut off inserts and other cemented carbide clamped inserts made as per our customers' requests.

Cemented carbide turning inserts

Turning is a metalcutting process used for the generation of cylindrical surfaces. Typically the workpiece is rotated on a spindle and the tool is fed into it radially, axially or both ways simultaneously to give the required surface. The term turning, in the general sense, refers to the generation of any cylindrical surface with a single point tool. More specifically, it is often applied just to the generation of external cylindrical surfaces oriented primarily parallel to the workpiece axis. The generation of surfaces oriented primarily perpendicular to the workpiece axis are called facing. In turning, the direction of the feeding motion is predominantly axial with respect to the machine spindle. In facing a radial feed is dominant. Tapered and contoured surfaces require both modes of tool feed at the same time often referred to as profiling.

The cutting characteristics of most turning applications are similar. For a given surface only one cemented carbide mechanical clamped inserts is used. This turning insert must overhang its holder to some extent to enable the holder to clear the rotating workpiece. Once the cut starts, the turning inserts and the workpiece are usually in contact until the surface is completely generated. During this time the cutting speed and cut dimensions will be constant when a cylindrical surface is being turned. In the case of facing operations the cutting speed is proportional to the work diameter, the speed decreasing as the center of the piece is approached. Sometimes a spindle speed changing mechanism is provided to increase the rotating speed of the workpiece as the tool moves to the center of the part.

With the break through of CNC machines, milling operations are increasingly replacing other conventional machining operations in industries like the mould and die making industries, the automotive industries and the mining and machine tool industries. These modern machines are capable of removing heavy stock at rates faster than any other known method and also with considerably tighter tolerance.

Cemented Carbide Milling Inserts

Milling has become one of the most popular methods of machining in the modern industrial scenario of higher productivity.

With the break through of CNC machines, milling operations are increasingly replacing other conventional machining operations in industries like the mould and die making industries, the automotive industries and the mining and machine tool industries. These modern machines are capable of removing heavy stock at rates faster than any other known method and also with considerably tighter tolerance.

The goal of all the manufacturing industries is to achieve minimum cost per piece or maximum production rate on a given machining operation. This can be achieved first by the correct selection of the application process and having chosen the process, the next step involves the correct selection of tooling and parameters.

Cemented carbide mechanical clamped inserts have helped in making this second step of selection much easier, requiring only a simple economic analysis of the machining operation to determine the optimum cutting speed yields minimum cost per piece or maximum production rate.

Cemented carbide mechanical clamped inserts today are available in a staggering number of geometric shapes, and generally used on cast iron and steel. Now we supply high quality cemented carbide mechanical clamped inserts.

All the cemented carbide milling inserts from Chinatungsten Online are customized.If you have any inquiry of our products, please feel free to contact us with sales@chinatungsten.com, sales@xiamentungsten.com. We are at service you.

sales@chinatungsten.com

sales@chinatungsten.com