Cemented Carbide Cutting Basic Theory Applications

If the chips can not be broken in the process of cutting chips out of control, it will seriously affect the safety of the operator and machine work properly, resulting in tool damage, reduce the quality of the machined surface, especially in the production of CNC machine tools and machine automation control chips ensure the normal cycle of automatic processing and processing chip unmanned.

The chips flow

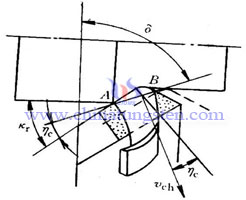

Must be effectively controlled in order to not damage the machined surface and facilitate the processing of chips, the flow of the chips. Since the chips flow is perpendicular to the direction of the respective cutting edge, so eventually the chips flow is perpendicular to the main direction of the end of the connection of the secondary cutting edge, typically the chips flow direction and the orthogonal plane angle ηc, ηc called chips flow angle. The main parameters that affect the direction of chip flow tool λs.

| Chips Flow Angle | Effects of Edge Inclination on Chips Flow |

|

|

| Controlling the chips flow in order not to damage the machined surface, facilitate the chip processing, so that the cutting carried out smoothly | a) The chips flow to the machined surface b) The chips flow to the surface to be processed |

Chips curl mechanism

The chips curl obstructions caused by the chips internal deformation or encounter chip breaker.

| Chips Curl Mechanism |

|

| a) Deformation differences cause chips curl b) torque cause the chips curl c) chips breaker cause chips curl |

Chip breaking measures

(1) Chip breaking measures - polished chips breaker

Grinding chips breaker on the cutting edge, the chips flow out from the turning tool front forcibly bend; break off, in order to achieve the chips breaker. The chips breaker is also for multi-edged blade. May not have the effect of cutting conditions vary, deliberately increased chip breaker. Chips breaker, by changing the feed rate and cutting depth a test: the feed rate and cutting depth control chips suitably bent, broken range, it is a prerequisite to play the role of chips breaker. So, according to the workpiece material, cutting speed and, chip breaker size on within its scope to change the feed rate and cutting depth.

(2) chip-breaking measures - changing the cutting parameters

The cutting parameters on the chip breaking is feed rate f, followed by the cutting depth ap, the minimum cutting speed vc. Increase the amount of feed, so that chip thickness the hch increases, prone to chip breaking when the subject of the collision. No significant effect on chip breaking cutting depth increase, and only when, while increasing the amount of feed to be effective chip breaking.

(3) Chip breaking measures - changing the tool angle

The main angle kr impact a major factor in chip breaking. The main angle kr increases, chip thickness hch increased easy chip breaking. Chip breaking turning tools are selected larger main angle> 60 º. Edge inclination λs chips flow changes, resulting in chip breaking the chips hit the machined surface or tool behind.

(4) Chip breaking measures - other chip breaking methods

Additional breaking means: to make the chips outflow reliable chip breaking, the rake surface fixed additional chip breaking stopper outflow chips collision block off crumbs.

The intermittent feed off crumbs: vibration cutting device, the cutting thickness variation, unequal section chips, chip breaking at the narrow cross-section.

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com