Cemented Carbide Drill Use

Chip processing

Processing cemented carbide drill, do not want the chips together into a strip of discharge. Especially in processing toughness relatively strong material, the chips long chip clogging, and thereby damage the tool. In this case, generally stop feeding, chip removal and then continue processing in this way is called phase-fed.

In order to cut off the chip, the method can be used to install a metal shim in the flute cemented carbide drill section.

Cemented Carbide Drill with Chipbreaker

Drill diameter and depth of the openings

The standard depth of the opening is maximum 5 times the diameter of the drill shank brazed cemented carbide blade type, maximum depth can be up to 7-8 times the drill diameter, and of course in that case the treatment of the chips is very important .

The use of the guide sleeve

when the work surface is not flat, in order to prevent the nose jitter and cause damage to the cutting edge, as far as possible using the guide sleeve, so that the cemented carbide drill work material can be cut in a straight line.

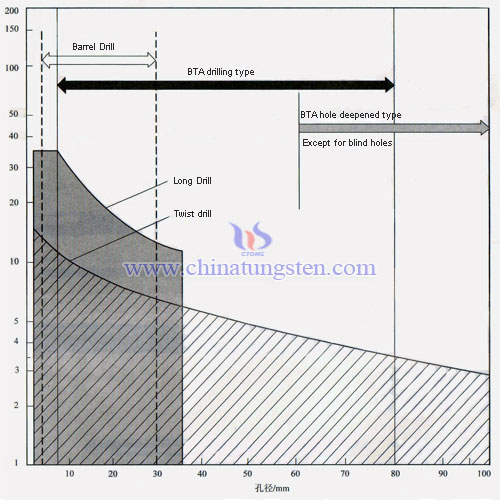

Pore size, deep hole, and tools selected roughly standard

To select drill type according to the relationship of pore size and pore depth

In the pore diameter of 20mm, hole depth of 12mm can be used twist drill hole depth is 15mm long drill hole depth is 15mm long drill hole depth is 50mm barrel drill, or use the open the BTA tool in the hole tools.

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com