Cemented Carbide Tools Milling Definition

Milling tools using the one or more combinations of the following basic milling cutting action: radial, peripheral or axial cutting. Changing the milling method, a milling tool can rotate about a tool axis direction of the feed movement along the cutting action. For example: the face milling cutting action carried out by the combination of a cutting edge, wherein the main use of the cutting action on the periphery, and to a certain extent also with the cutting action of the surface of the milling tool. Milling tool along the workpiece is rotated at right angles to the direction of radial feed. The three edges milling major milling tool milling around the cutting edge. The milling tool is parallel to the rotation about an axis tangential feed. Plunge milling mainly use the tool end face or the end of the cutting edge, and through the axial feed, to perform local milling effect.

Milling characteristics

① The milling cutter is a multi-blade cutter teeth simultaneously working efficiency more, can be used stepped milling, high-speed milling can also be used, so productivity is high.

② Milling process is an intermittent cutting process, cutter teeth cut and cut out the moment of the workpiece to produce shock and vibration when the same as the natural frequency of the vibration frequency and machine vibration will intensify, causing the cutter tooth chipping, or even damage to the machine zero parts. Further, due to the periodical variation of the milling thickness leads to the milling force changing. This also can cause vibrations.

③ Milling cutter to work a short time, although beneficial cutter heat and cooling, but periodic thermal deformation would lead to the cutting edge of the thermal fatigue crack, causing tooth chipping peeling off into.

Milling, including peripheral milling (climb milling) and face milling (symmetry milling, asymmetric climb milling and asymmetric cut milling)

Milling parameters and units

| Dc=cutting diameter | mm | Zc=effective teeth | pieces |

| Im=processing length | mm | kc1=materials unit cutting force (hex=1mm) | N/sq m |

| De=effective cutting diameter | mm | ||

| ap=cut depth | mm | n=spindle speed | rev / min |

| Pc=cutting net power | kW | ||

| ae=cutting width | mm | η=efficiency | |

| Vc=cutting speed | m/min | ||

| Q=metal removal rate | Cm3/min | Kr=main cutting edge angle | degree |

| Tc=contact cycle | min | Vc0=cutting speed constant | |

| Zn=cutting edges total number on tools | pieces | Cvc=cutting speed correction factor | |

| Mc=The improvement of cutting force (kc) caused by chip thickness | |||

| fz=feed rate per tooth | mm | ic=inscribed circle | |

| fn=feed amount per revolution | mm | ||

| vf=table feed (feed rate) | mm / min | ||

| hex=maximum chip thickness | mm | ||

| hm=average chip thickness | mm |

| Milling Basic Definitions | Milling Basic Definitions |

|

|

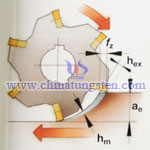

| Maximum chip thickness (hex), Average chip thickness (hm), Feed amount per tooth (fz) | Cutting depth (ap), Cut width (ae) |

The main angle of the tool (kr) or the main cutting edge angle for milling cutting trough, the decisive factor is the impact of the cutting force direction and the chip thickness. According to the different effects of the cutting action, insert geometry has been simplified into three ranges of applications: light (L), heavy duty (H) and ordinary (M) trough.

Tooth pitch (u): is the distance between each tooth on the milling cutter. It represents the distance between the same points on the point of a cutting edge to the next cutting edge. The milling cutter is divided into sparse teeth (L), fine-toothed (M) and the super-secret (H) pitch three kinds. Different tooth pitch have different effects for the stability of the process, power consumption, and suitable for processing materials. Ranging tooth pitch means the toothed interval on the tool are not equal. This is an effective method to solve the vibration problem.

| Milling Basic Definition | ||

|

|

|

| The light cut trough-L& Pitch sparse (-L) | The ordinary grooved-M &Dense tooth pitch (-M) | The heavy grooved-H &Ultra-dense form (-H) |

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com