Double-edged & Multi-edge Boring Tools

Double-edged boring tools

The double-edged boring tools have two symmetrical cutting edges to participate cutting, cutting radial forces can cancel each other out, and are unlikely to cause vibration of the workpiece aperture size and precision boring tool radial size guarantee.

The double-edged boring tools include fixed knife, the chute double-edged boring cutters and floating boring tools.

(1)Fixed double-edged boring tools

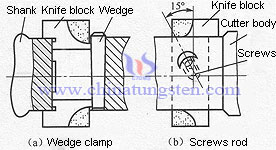

Fixed-boring tools are mainly used for rough boring or semi-fine boring a hole diameter greater than 40mm. Made by the high-speed steel piece knife block can also be cemented carbide welded or indexable type. In operation, the knife block through the wedge or the clamping screws of the two inclined arbor. Installed knife the block relative Arbor position error will cause Aperture to expand, so the square hole on the knife block and arbor with the higher accuracy requirements, and the square hole on the arbor axis of verticality and symmetry error should be less than 0.01mm.

| Fixed Double-edged Boring Tools |

|

(2)Chute double-edged boring tools

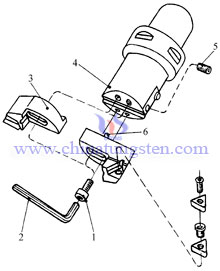

As shown are chute double-edged boring tools. The boring head convex shoulder at 4 groove cutter body with screws it pressed on the cutter body. Adjust the size, slightly loosen the screws, you turn the adjustment screw 5, to promote the boring tool head pin 6, to move along the slot to adjust the size of the boring head. The boring range Φ25 ~ 250mm is widely used in CNC machine tools.

| Chute Double-edged Boring Tools |

|

| 1 - Screw; 2 - Hexagon wrench; 3 - Boring head; 4 - Knife body; 5 - Adjustment screws; 6 - Pin |

(3)Floating boring tools

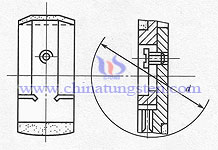

The fine boring is most of the floating structure. As shown is floating boring tools structure, and to guarantee the required aperture size by adjusting the radial position of the cutting edge. The boring tools knife block loaded arbor square hole clearance fit, without clamping, rely on cutting role on both sides of the cutting edge facing away from the force from to dynamic balancing its cutting position, which can automatically compensate for installation by the tool error and boring bar radial circular bound generated by the processing error. The hole precision machining using the boring tool up to IT7 ~ IT6, surface roughness Ra of 1.6 ~~ 0.4μm. Knife block floating in the arbor, so I can not correct the bore straightness errors and mutual position error. Tube and fittings floating boring tools are mainly applied to single small batch production of large diameter holes, particularly suitable the fine boring aperture (d> 200mm) and deep (L / d> 5) holes.

Floating boring tools cutting edge angle Kr is usually taken as 1 ° 30 'to 2 ° 30' Kr angle is too large, axial force will increase the boring tools knife hole friction is too large, will lose a floating role. The boring pole mounted floating boring tool square hole symmetrical to the centerline of the boring bar, so in the anterior horn, posterior horn, must take into account the changes in value of the working angle to the cutting light and the quality of the machined surface. The floating boring cutting the amount of general admission: Vc = 5 ~~ 8m/min, f = 0.5 to 1 mm / r, ap = 0.03 ~~ 0.06mm.

| Floating Boring tools |

|

Multi-blade boring tools

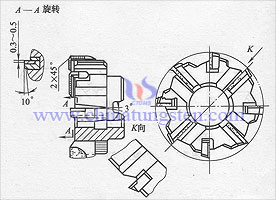

Multi-blade boring tools in circular cutter head circumference inlaid with more than two single-edged boring head, as shown. Boring, each tooth to work, improve productivity, and suitable for the hole roughing.

| Multi-blade boring tools |

|

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools,cemented carbide boring tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com.

sales@chinatungsten.com

sales@chinatungsten.com