Single Blade Boring Tools

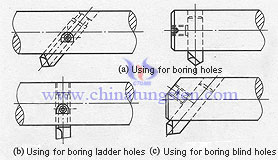

Single blade boring tools cutter heads' structure is similar with turning tools ,the heads mounted on the arbor, a position according to the machining hole aperture size, by manual manipulation, with the screw heads. Head and boring bar axis vertical can be boring through holes, tilt installation can be boring blind holes.

The single blade boring tools structure is simple and can be corrected position deviation of the original hole axis skew and small, wide adaptability, can be used to roughing, semi-finishing or finishing. However, the size of the aperture size of single edge boring knives are boring to rely on manual adjustment of the boring tool head suspended elongation to ensure more trouble to work, coupled with only a single edge boring tool main cutting edge, so the lower production efficiency, used for single and small batch production.

The boring processing small-diameter single-edged knife is usually made of the overall processing of large diameter single blade knife can be made machine clip-on or machine folder indexable. Boring bar should not be too thin and too long to generate vibration in order to avoid cutting. To make the boring head in the boring bar have a greater installation length and having adequate position the compression screw and the adjusting screw, in the boring blind bore or a stepped hole boring head tilt angle δ in the installation of the boring rod Average take 10 ° to 45 °, boring through holes take δ = 0 °, in order to facilitate the manufacture of the boring bar. Usually compression screw from the boring bar face or top surface to compress the boring head.

Single blade boring tools clamping way as shown in the figure.

| Single Bade Boring Tools Clamping |

|

| Boring Types and Scope of Applications | ||||

| Types | Diagram | Process Characteristics | Scope of Applications | |

| Boring tools rotation, Workpiece for movement |

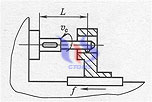

Boring Lathe Boring |  |

The table driven workpiece feed motion, boring bar overhang length L constant, the shape accuracy of the boring bar the longitudinal deformation of the holes no effect; work feed direction skewed or non-linear bore axis will produce the position error | Suitable for processing general hole |

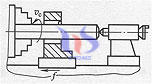

| Lathe Boring |  |

Apron driven workpiece for the movement, one end of the boring bar clamping jaw self-centering chuck and the other end with a top supporting, rigid | Suitable for processing longish hole | |

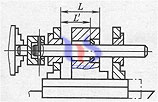

| Boring Mode Boring |  |

Boring bar support in boring mode two guide sleeve, better rigidity, boring bar floating connection with the machine tool spindle, workpiece feed along with the boring mold, boring tool from the support sleeve from the distance from L to L '. If with ordinary boring cutter to bore, deformation of the boring bar causes the workpiece longitudinal shape error; switch Twinblades floating the boring knife bore, due to radial forces cancel each other, can avoid the above-mentioned longitudinal shape error. Feed direction with respect to the parallelism error of the spindle axis positional accuracy of the processing of each hole | For hole machining rely boring modulus guarantee | |

| Boring Tools Reversed and Feed |  |

Boring machine spindle box or ram feed, to ensure the consistency of the aperture | Suitable for processing a variety of holes | |

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools,cemented carbide boring tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com.

sales@chinatungsten.com

sales@chinatungsten.com