Cemented Carbide Drills Apex Angle118°

Why cemented carbide drill apex angle is 118 °?

Hardware store, if you say: "Please take cemented carbide drill diameter Ф10mm to me", the shopkeeper will ask: how many the cemented carbide drill vertex degrees? "Then he went on to say:" We here is the apex angle, it will come up with a twist drill vertex angle of 118 °.

Cemented carbide drill for sale on the market apex angle is 118 °, why?

Excellence

I heard that the cemented carbide drill apex angle are generally 118 °. And does not seem to rely on theoretical calculated.

Workpiece materials, the use of steel up, drilling such metal carbide drill apex angle are 118 °, which is concluded by long experience.

In a factory, when I asked: "Why cemented carbide drill top corner to choose 118 °?" The worker replied: "That is a matter of course." Simply put, it seems workers excellence.

Why cemented carbide drill apex angle 118 ° is better than it?

Change cemented carbide drill apex angle

Let's analyze the change apex angle drill cutting effect.

| Cutting Effects after Changing Cemented Carbide Drill Apex Angle | ||

|

|

|

| Duo to apex angle 2Ф is different, cutting force (F), facing away from the force (Fp), feed force (Ff) will change. | ||

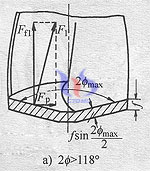

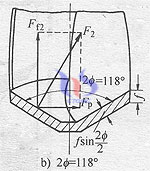

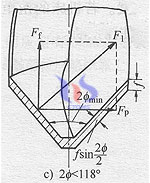

Figure b the apex angle is 118 °, the apex angle of the three graphs as a> b> c. The line portion of the profile is the drill half rotation when the feed amount of ƒ, is drilled by the two cutting edges and a sectional. The sectional areas are ƒD, D is the drill diameter. Thus, actual drilling, the drill bit by three force (cutting force, the back force, feed force) of the feed amount of the drill is the ƒ to. After the rotation of the drill, the cutting edge corresponding to the feed amount of ƒ to 'becomes ƒ' = ƒsin2Ф / 2, i.e. 2Ф the smaller, ƒ 'smaller. The chip thickness is reduced by the order of a, b, c. Well, the order of the size of the cutting force for c> b> a.

Fig a minimum of cutting force, feed force due to the cutting force is close to the spindle direction, so a larger; contrast thereto, Figure C of the cutting force larger back force is small, i.e. the size of the backward force of the order of A> B > c.

As we all know, the smaller 2Ф is, more pointed the drill bit, so that the smaller the back-force. Does not consider whether the cutting edge is sharp on the basis of, the drill apex angle of 180 °, the feed force can become very large.

Now that you already know that the apex angle of the smaller, smaller pressure drilling, then just try the point angle smaller some can not it do? As a result, there is no need to 118 °, 90 ° or 30 °, but proved that it is not feasible.

Cemented carbide drill the rake angle γ0 smaller, perpendicular to the component of force to feed back force Fp will increase, as already described above clearly. This back-force size and feed force opposite apex angle larger the smaller. To make carbide drill rotation and discharging chips requires a lot of torque.

Compare Fig a with c, from the cutting edge at right angles to the feed amount of the ƒ 'regardless of the size of the cutting force, but the actual drilling, the torque generated by the Figure c is several times the Fig a.

Processed tapered hole with a tapered reamer very clear, even if the allowance is very small, still need a lot of torque, and therefore, the tapered reamer is seen as the apex angle 2Ф becomes small triangular drill can understand. So, as long as the can provide a great torque, the great power of the machine feeding force small to use the apex small drill can. But it alone is not enough to improve the machine power.

Anyway, the actual cutting is carbide drill, no matter how much torque the machine tool, the cemented carbide drill bits must still be able to withstand a sufficiently large strength. The torque of the machine is too large,cemented carbide drill itself will not bear wring.

As described above, the point angle of a cutting edge determined after another will tilt, this way, to grind the drill apex would be quite difficult. Therefore, after a long period of experience accumulated, the best steel cutting carbide drill with an apex angle of 118 °, 118 ° becomes the standard apex angle.

Well,cemented carbide drill apex angle is 118 °? In fact, 118 ° just standard angle for drilling steel is most appropriate.

However, when processing if replace the workpiece material, it is better to change the size of apex angle.

Force feed back force of view, 118 ° cutting effect is good, but the actual drilling, tool life must consider. From this point of view, according to the workpiece material to change apex angle is very common.

Carefully observing cemented carbide drill bits will be able to know that when cemented carbide drill apex angle is 118 °, the cutting edge is a straight line. However, in the production site, depending on the material, drill apex angle may be greater than 118 ° or may be less than 118 °. Becomes the curve of the cutting edge in this case, chips corresponding to the shape may vary.

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com