Cemented Carbide Twist Drills

Cemented carbide twist drills are more complex shape of the pole slot machining tools.

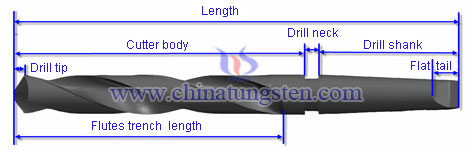

Cemented carbide twist drills composition: twist drill can be divided into three parts according to their different function.

The drill shank (Shank): cemented carbide twist drills head for the clamping portion, and for transferring drilling the required power (torque and axial force).

Diamond neck (Neck): in the transition between the cemented carbide twist drills knife and drill shank. It usually used as a grinding wheel retraction empty knife slots.

Drill body (Body): cemented carbide twist drills working portion of the drill bit, by the cutting portion (i.e., the drill tip) and the guide portion.

| Cemented Carbide Twist Drills Composition |

|

| Drill shank, drill neck, drill body composed cemented carbide twist drills. |

Cemented carbide twist drills structural parameters

| Cemented Carbide Twist Drills Structural Parameters |

|

| Cemented carbide twist drills structural parameters are the independent parameters to determine the geometry of the cemented carbide twist drills. |

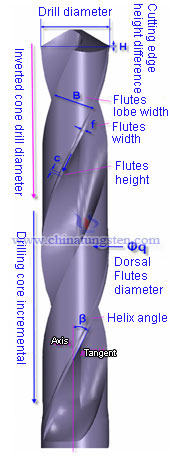

Cemented carbide twist drills structure parameter refers to the size or angle of the drill in manufacturing control; they are independent parameters to determine the geometry of the twist drill. Include the following:

(1) Diameter d: with the two-edged twist drill cutting part of the measurement, the distance between the selection of a standard series size.

(2) Inverted cone diameter: means away from the cutting portion of the diameter is gradually made small in order to reduce the friction of the edge with the hole wall, equivalent vice declination. Drill inverted cone is about 0.03 ~ 0.12mm/100mm, a larger diameter inverted cone is also large.

(3) Drill core diameter do: It is a two-edged ditch tangent to the diameter of the circle. It affects the twist drill rigidity of Chip-section. Diameter greater than 13mm twist drill, do = (0.125-0.15) do drill core made the 1.4 ~ 2mm/100mm positive taper to increase the stiffness of the drill.

(4) The edge of the blade with blade helix, helix angle ω expand to the plane in a straight line with the angle of the twist drill bit axis of the helix angle.

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools,cemented carbide twist drills, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com