Cemented Carbide Planing Inserted Tools

Planing, slotting processing characteristics

(1)Planing

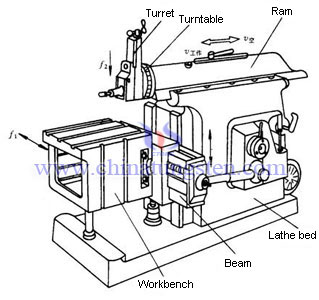

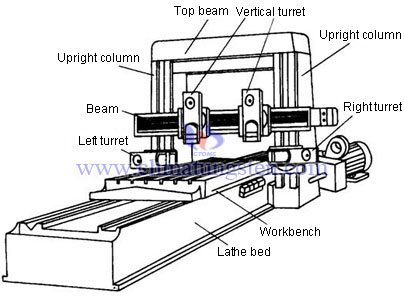

Planing is generated between the tool and workpiece relative to the linear reciprocating motion of the workpiece surface to achieve a metal cutting method, mainly used for the machining plane, the grooves and the molding surface. Therefore, planing speed is impossible too high, lower planing productivity. Planed is smoother than milling machining. Planning precision is generally up IT8 ~ IT7, the surface roughness up to Ra6.3~ 1.6 μm, fine planing flatness up to 0.02/1000 and surface roughness of 0.8 ~ 0.4μm. Common planing machine is the Ngau Tau planing cutting planer and gantry planing planer.

| Planing Machine - Ngau Tau Planing Planer | Planing Machine - Gantry Planing Planer |

|

|

| The Ngau Tau planing planer because of ram and turret named after the shape of a "cow". Apply to the planing length of not more than 1000 mm, small and medium-sized parts. Planing accuracy generally IT9-IT7, the surface roughness Ra of 6.3 to 3.2um. The main parameters of the Ngau Tau planing planer is length Max.planing. | Gantry planing planer because it has a gantry-frame is named. Mainly used for planing large workpiece machining large flat, especially long, narrow plane, general planing workpiece width of one meter, more than 3 meters in length. Gantry planing planer main parameter is the maximum width of the planing. |

Planing characteristics

①Planing main movement is planer tool relative to the workpiece cycle reciprocating linear motion, the feed movement workbench relative turret intermittent linear motion.

②Planing is interrupted cutting. Each reciprocating stroke planing planer tool larger impact will be cut into the workpiece, the processing requirements of the system has sufficient rigidity, workpiece and tool clamping firm; the main movement commutation must overcome a greater inertia, so planing cutting speed can not be too high; return trip planer tool is not involved in the planing, resulting in the loss of air travel, the productivity is low.

③Planing not only able to process plane, bevel, and uneven surfaces. Planing also processes a variety of surfaces, a wide range of technology.

④planing machining accuracy IT10 ~ IT7, the long rail surface for large machine tools can planing and grinding ".

(2)Slotting

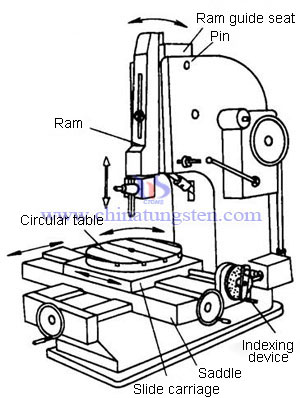

Slotting cutting and planing is basically the same, just slotting cutting in the vertical direction. The slotting is equivalent to vertical planing.

The main movement of slotting is down reciprocating linear motion of the tool. Slotting suitable for single piece or small batch production processing bore keyway or spline hole machining square hole and polygon holes. For blind hole or obstacle shoulder hole keyway slotting is almost the only method of processing. The Slotting used for machine repair workshop and single-piece and small batch. As slotting machine tool outline drawing.

| Slotting Machine |

|

| Bolt slotting generally used for slotting a single piece, small batch production of the workpiece, ordinary latch-seater keyway bolt slotting machine, gantry latch slotting and mobile Bayonet slotting. Slotting processing, the ram driven bolt inserted knife for linear reciprocating motion along the vertical direction, the main movement of the slotting process. The workpiece is mounted on a round work table; the circular table can be realized to the longitudinal, transverse and circumferential directions of the intermittent feed motion. In addition, the use of the indexing device, the circular table can also be a circumferential indexing. The ram guide seat and ram can be rotated about the pin in the vertical plane relative to the column tilted from 0 ° to 8 °, for slotting chute and bevel. |

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools,planing and slotting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com