Cemented Carbide Slotting Tools

Cemented carbide slotting tool types

Cemented carbide slotting tool many different types, mainly monolithic cemented carbide inserted knife and modular cemented carbide inserted knife two structures. The monolithic cemented carbide slotting tool of the cutter head with the shank integrally; modular cemented carbide slotting tool of the cutter head and the shank is divided into two parts, the shank can be done according to the machining situation thick and short, rigid, head free exchange, used widely.

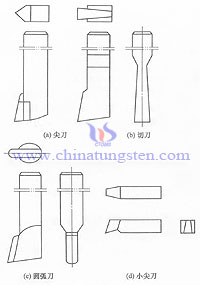

Cemented carbide slotting tools processing nature is divided into and coarse cemented carbide slotting tool and fine cemented carbide slotting tool, knives, and cutters can be divided according to their use, forming knife. The knife used for coarse interpolation, or slotting polygon hole. The cutter is commonly used to slotting the rectangular-shaped groove and polygon holes. Forming knife needs sharpening made according to the shape of the workpiece surface, forming knife angle, arc and toothed shape into.

Commonly used cemented carbide slotting tools types are shown in Fig.

| Cemented Carbide Slotting Tool Types |

|

The cemented carbide slotting tool cutting part of high-speed steel and cemented carbide materials, alloy tool steel can also be used. Machining workpiece of ordinary steel and non-ferrous materials, commonly used in high-speed steel processing high hardness steel and cast iron workpieces are often used in cemented carbide. Since modular slotting tool manufacturing convenience, low cost, and a knife head can be processed into various shapes require sharpening, fixture replacement is very convenient, as long as the exchange of a knife head to the rough, finishing and forming process, so choose, priority modular slotting tool. However, modular slotting tool due to the restriction of the clamping heads apertures in the processing, when the narrow groove or blind holes can not be used.

Monolithic cemented carbide inserted knife from clamping heads restrictions, the head part made smaller size as needed for the processing of the same size as the holes Arbor strength than modular plug cutter suitable for machining small holes, slots, blind holes (or empty knife slots small surface) and short foot surface. Integral slotting tool drawback is irreplaceable heads, each head size smaller, the entire knife was soon scrapped, not economic.

Furthermore, due to the integral cemented carbide slotting tool Arbor Size can not do much, inserted knife mounted in a turret on the tool out longer, and therefore easily deformed or damaged, so the quality of the machined surface can not be guaranteed, the application when slotting usage is also restricted.

Commonly used cemented carbide slotting tool and its use:

Knife - coarse interpolation or slotting polygon hole

Cutter - slotting a right angle-shaped groove and polygon hole

Arc knife - slotting forming surface

Chinatungsten Online can provide various sizes and grades of cemented carbide slotting tool , non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com