Side Milling Cutting Edge Spirals

Cutting edge spiral under occasions of side milling (aluminum shape processing)

The cutting edge, also called the main cutting edge or main blade, is the intersecting line of the front and rear flank, the cutting edge shoulder main cutting work.

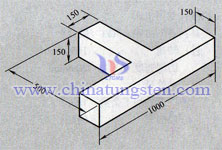

| Workpiece material:Duralumin | Parts diagram |

| Processing machinery: the ultra-high-speed vertical Profiling Mill |  |

| Tools: two φ80mm end mills (rotation angle of 15 °, radial 0) | |

| Conditions: rotation speed 3200r/min Cutting speed 800m/min Feed rate 0.05mm/r Cutting depth 1.5mm Cutting width 150mm Cutting fluid Use Side milling machining |

Results: The usual practice is to use the straight edge end mills cutting edge for side milling machining, but the poor accuracy of machining by the cutting edge of the machined surface, the need for the second cutting. Use 15 ° spiral end mills to resolve the problem.

|

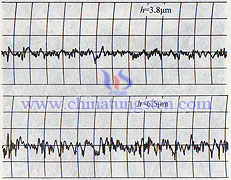

| Small surface roughness of the spiral blade (upper) (lower) than the straight edge processing |

Summary: The cutting edge is a straight edge, the vibration of the cutting will be directly affected by the cutting surface. The cutting edge of the straight edge rake angle is smaller than the oblique edge; it is processed by the cutting edge machining surface accuracy is not always ideal. Now the measures taken to reduce fever is using oblique edge and Cutting fluid (mist) at the same time.

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com