Cemented Carbide Tool Cutting Edge Defect and Honing

Cemented carbide tool cutting edge defect and honing (The outer periphery cutting of vehicle parts)

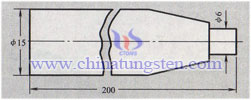

| Workpiece material:S20C(HS20) | Parts diagram |

| Processing machinery:transformation lathe |  |

| Tools:E22R—33(TNPR331)X407 | |

| Conditions: rotation speed 2200r/min Cutting speed 100m/min Feed rate 0.15~0.2mm/r(oil pressure) Cutting depth 4mm(max) |

Results: cemented carbide cutting edge defect occurs, the life will be shortened. Cemented carbide tool cutting edge honing can increase tool life.

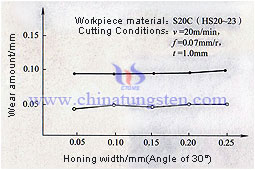

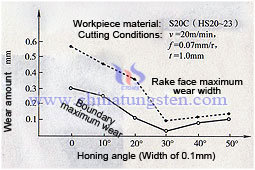

Summary: In general, cutting steel when necessary to carry out the cutting edge honing of cemented carbide tool, cemented carbide cutting edge honing can prevent the fragmentation of the cutting edge and glue attachments cutting edge processing, or due to the cutting the vibration generated by the chipping, and the gap. Honed width of the cemented carbide cutting edge is approximately 0.5-0.8 times the feed amount.

| Relationship between cemented carbide tool cutting edge honing width and wear amount | Relationship between cemented carbide cutting edge angle and wear amount |

|

|

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com