Cemented Carbide Turning Tools Chipbreaker

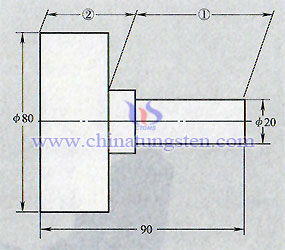

Profiling lathe with cemented carbide tools chipbreaker (automotive parts ablation profile)

| Workpiece material:S55C(HS35) | Parts diagram | |||||||||||||||

| Processing machinery: Profile Lathe |  |

|||||||||||||||

| Tools: E22L-44(TNUB432 TX10D) |

||||||||||||||||

Conditions:

| ||||||||||||||||

Results: processing size 2 chips entangled knives, turning tools with cemented carbide blade defect occurs. Cemented carbide Cutters chipbreaker after changed, to avoid cemented carbide turning tool inserts of the defect, it also becomes possible to automate the cutting.

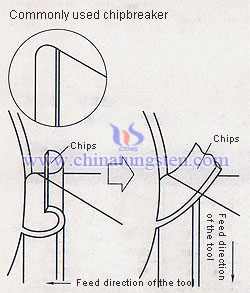

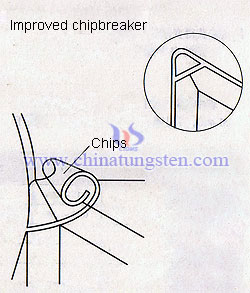

| Usually used cemented carbide turning tools chipbreaker | Cemented carbide turning tools chipbreaker after improving |

|

|

| Cutting direction and chips flow of the chipbreaker when use usual cemented carbide turning tools. | The swarf flow of improved cemented carbide turning tools chipbreaker |

Summary: Impact swarf to be roll-shaped portion is of a triangle formed by the contact surface of the shearing surface and the cutting edge region (as shown in the hatched portion), the main problem is the presence of energy of this region are sufficient to enable the chip become roll shape. From the longitudinal feed change to the feed, the flow of the chip will be changed, i.e. the chips were always flowing along the perpendicular direction of the blade along the blade in an oblique direction into flow. When the amount of decrease of the rake angle is very small, but because of the greatly reduced only by the shoulder of the cemented carbide tools, chipbreaker to make chip deformation energy, so chip elongated outflow, so that winding on to the tool or workpiece . The energy supplement In this case, the need for deformable portion, that is, how to efficiently use carbide turning tool chipbreaker shoulder to obtain deformation can become a problem which must be solved.

Approximate standards of selectingcemented carbide turning tools chipbreaker

Sharpening chipbreaker purpose is to make the chip through chipbreaker, so that the internal stress of the swarf generated flip forced it is deformed and broken in the turning tool rake face. chipbreaker use is divided into finishing, semi-finishing and roughing chipbreaker. Chips underlying chipbreaker groove bottom the cutting process, the chips before from cemented carbide Cutters flank outflow strongly friction will generate a lot of heat, constantly cutting heat transmitted from the chip to the cemented carbide Cutters blade, causing the blade to produce wear. In the chipbreaker groove bottom is cut out a dimple can make a contact area of the blade with the chip bottom reach at least to reduce the wear of the blade, and to improve the life of the blade.

Listed in the table with the E-type TAC cemented carbide Cutters processing SCM-440, the cutting speed of 100m/min corresponding to various carbide tools chipbreaker shape back, cutting depth and feed to the amount of the relationship. The values in the table for the feed amount in the range.

| Cutting depth Turning tools chipbreaker code | 0.5 | 1.0 | 2.0 | 3.0 | 4.0 | 5.0 | |

| P-class blade | A | above 0.075 | 0.15~0.30 | 0.15~0.25 | |||

| B | above 0.15 | 0.20~0.30 | 0.20~0.30 | ||||

| C | 0.20~0.34 | 0.20~0.32 | 0.20~0.32 | 0.20~0.32 | |||

| D | 0.25~0.70 | 0.25~0.64 | 0.25~0.52 | ||||

| E | 0.30~0.70 | 0.30~0.65 | 0.30~0.60 | ||||

| U-class blade | F | 0.15~0.30 | 0.10~0.25 | 0.15~0.20 | |||

| G | 0.20~0.70 | 0.25~0.5 | 0.20~0.40 | 0.20~0.33 | 0.20~0.29 | ||

| H | 0.25~0.84 | 0.25~0.63 | 0.25~0.52 | 0.25~0.45 | 0.25~0.40 | ||

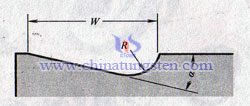

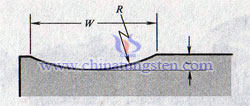

| P class cemented carbide turning tools chipbreaker size | U class cemented carbide turning tools chipbreaker size |

|

|

| turning tools chipbreaker Code | W | α/(°) | R |

| A | 1.2 | 14 | 0.4 |

| B | 1.5 | 14 | 0.5 |

| C | 2.0 | 14 | 1.0 |

| D | 2.5 | 10 | 2.0 |

| E | 3.0 | 10 | 2.0 |

| turning tools of chipbreaker Code | W | t | R |

| F | 1.2 | 0.10 | 1.8 |

| G | 1.8 | 0.15 | 2.8 |

| H | 2.3 | 0.20 | 3.4 |

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com