Cemented Carbide End Mill Honing Effect

Cemented carbide end mill honing effect (trench, step processing)

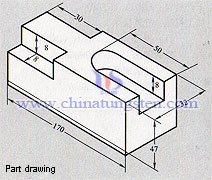

| Workpiece material:SK7(HS28) | Parts diagram |

| Processing machinery: milling fixture |  |

| Tools: large helix angle (φ16mm) end mills | |

| Conditions: Cutting speed 60m/min Feed rate 0.05mm/r Cutting depth 4mm |

Results: it is very difficult to cutting steel with cemented carbide end mills, as cutting cemented carbide end mills often broken. The main reason is cutting vibration and swarf the wound caused by the breakage of carbide end mill. To such cemented carbide end mills having large helix angle need for honing, in order to prevent the occurrence of these phenomena. After honing cemented carbide end mills the ideal cutting effect.

|

|

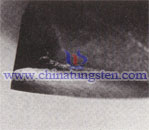

| If the flute is small, end mills will be damaged | End mills cutting edge after honing |

Summary: When the groove machining or extrusion processing Cemented carbide end mills, carbide end mill breakage occurs swarf clogging the flute and chips outflow direction does not correspond, it is necessary cemented carbide end mills cutting edge to take an oblique direction. Thus, the outflow has been improved, but the ensuing problem is that the shape of a cemented carbide end mills cutting edge prone gap. For the protection of the cutting edge, carbide end mill, it is necessary to be honed. Carbide end mill

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com