Barrel Drill Use Instance

Barrel drill instance (the automobile parts oblique hole machining)

| Workpiece material:SCM4(HS35) | Parts diagram |

| Processing machinery: barrel drill special machine |  |

| Tools:φ6x350x19.05(G2F) | |

| Conditions: Rotation speed 4200r/min Cutting speed 80m/min Feed rate 0.05mm/r Cutting depth 50~100mm |

Results: HSS twist drill for drilling process in use after the barrel drill, improve the accuracy of the barrel drill, extend the life of the barrel drill to achieve the effect of cost-cutting.

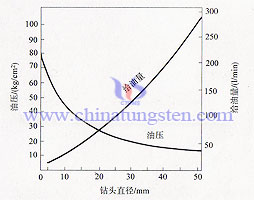

Summary: deep hole barrel drill is first used in weapons manufacturing industry, hence the name barrel drill. In order to effectively use the barrel drill, must maintain a certain relationship between the hydraulic and oil amount. Barrel drill work process if the oil pressure is too low, the chip will be stuck in the barrel drill pipe, barrel drill damage the barrel drill must pay attention to this point.

|

|

|

| Barrel drill guide sleeve used for the processing of oblique hole | Chips generated after barrel drill cutting | Relationship between drill diameter and oil amount, hydraulic |

Oil amount of barrel drill corresponds to machining hole diameter

| Processing aperture/mm | cutting oil amount(ι/min) | ||||||

| Hole depth/mm | 150 | 300 | 450 | 600 | 1000 | 1300 | |

| 4.8~6.3 | 7.6 | 11.5 | 11.5 | 11.5 | 11.5 | 11.5 | |

| 6.3~9.5 | 15 | 15 | 19 | 23 | 23 | 23 | |

| 9.5~12.7 | 19 | 23 | 30 | 38 | 42 | 42 | |

| 12.7~19.0 | 27 | 30 | 38 | 49 | 64 | 64 | |

| 19.0~25.4 | 46 | 57 | 76 | 115 | 115 | 115 | |

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com .

sales@chinatungsten.com

sales@chinatungsten.com