Special Drill for Hard Cutting Materials

Special drill for hard cutting materials (High-manganese steel hole machining)

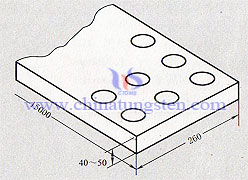

| Workpiece material: high manganese steel | Parts diagram |

| Processing Machinery: Radial Drilling |  |

| Tools:φ10x196xMT3(Microalloy) | |

| Conditions: Rotation speed 160r/min Cutting speed 5m/min Feed rate 0.07mm/r Processing depth 30mm Cutting fluid Use |

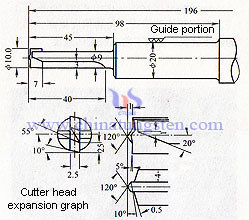

Results: HSS special drill bit to process, but the processing is very difficult, and the pass rate is very low. Of special drill can now be used in the HSS drill head plus the "H" of the micro-alloy blade, as shown.

|

| The edge of the "H" plus micro-alloy special drill |

Summary: difficult to cut materials has the result of the nature of the material difficult to process, hard cutting materials processing, cutting his way pause, hard cutting materials because of the cutting heat hardening. And then just stop place to continue drilling, the cutting edge will slip in the hardened surface; can not afford to feed force defect.

Resolve this problem must be possible to put cutting sharpening too sharp, but also allow the smaller bending radius of the chip, so the cutting edge is designed as a special bit ("H" drill).

Use the guide sleeve to weaken the special drill tip jitter; it is more efficient to process hard cutting materials with special drill bit.

Chinatungsten Online can provide various sizes and grades of cemented carbide cutting tools, non-standard products are also customized according to customer requirements. Welcome to consult and purchase sales@chinatungsten.com, sales@xiamentungsten.com.

sales@chinatungsten.com

sales@chinatungsten.com